Tag: processing

In the Fiber Room

In the Fiber Room

|

| There are almost always buckets of fleece soaking either to wash or dye |

|

| There is dyeing… |

|

| and more dyeing |

|

| Which leads, of course, to large screens of fleece drying |

|

| More of Blackberry’s fleece being processed for blog friend, Michaele |

|

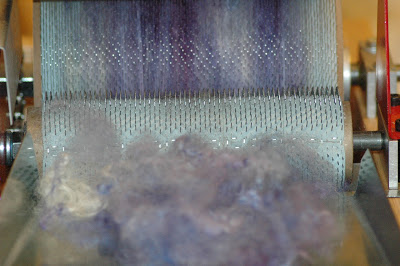

| More carding…lamb’s wool and mohair |

|

| and more spinning… this time Hera’s mill roving |

Heather Lavender Processing

|

Inspired by all the heathery knits out there this year, we rolled up our sleeves and went to work. We dyed part of Boy George’s lamb locks different shades of purple, periwinkle and lilac, gently teased the locks apart, combined it with some of his natural locks and a little mohair. A couple passes through the carder, and here we have it – our interpretation – some lovely Heather Lavender Spinning Batts.

We are trying something just a little bit different with the second group of spinning batts. Along with the batts that are combination of natural and purple lamb locks, we included two batts that are primarily purple and one batt that is natural. They are all 30% mohair. We think this group of batts will spin up into some lovely yarn for a project with some accent color or stripes.

Boy George’s lamb locks (Border Leicester – Coopworth – Wensleydale) are even more soft and lustrous with the addition of the mohair. We are so happy with the end result that we just might have to get back to the carder and spin up some of these for a sample knit!

The Fiber Room in Winter

|

| skirting fleeces |

|

| soaking… washing |

|

| fleeces drying |

|

| dyeing lamb’s locks |

|

| carding… spinning |

|

| knitting… knitting… and well, more knitting |

The fiber room is a busy place as the winter weather drives us inside. There are always plenty of projects in varying states of completion. Much as each sheep has its own personality, each fleece is just a little bit different. The lock structure, crimp and curl, the color and luster all differ from fleece to fleece. It is a wonderful time of year as we get to enjoy the fruits of our labor and also share some of our beautiful fleeces with our great customers.

Fiber Love

|

| Athena – – Coopworth – Border Leicester Cross |

|

| Hera — Coopworth – Border Leicester Cross |

|

| Moe — Romney – Coopworth – Wensleydale Cross |

|

| Larry — Romney – Coopworth – Wensleydale Cross |

We just can’t wait to get our hands into these bags of fibery goodness, received last week from Davis Ridge Fiber Farm & Mill in Nettie, West Virginia. We met Jen and Brandon at the West Virginia Wild and Wooly Fiber Festival. Arriving with our four large bags of fiber in tow, we were shepherdess/s on a mission. We were thrilled to meet the Harden family, and equally thrilled that they are starting a fiber processing facility in West Virginia! We sent our ‘four bags full’ back with them to be processed into roving, and, well, you can see the results above.

It is tough to concentrate on the holidays surrounded by all this lovely fiber; next week may well see some shepherdess/s hiding from the family to do some post-holiday spinning!

Twenty-five Bags of Fleeces To Go

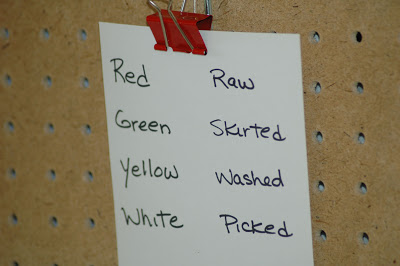

The New System

With some gentle nudging from Jonathan and Megan, we adopted the new system they developed to organize our fleece processing – must say – it is colorful, cheerful and effective.

We had some much appreciated help with the ‘triple-picking’ and some fiber room antics for entertainment.

Our skirting table was moved under a new LED light bulb, and in a short period of time on Saturday we had three skirted fleeces and about half a triple-picked lamb’s fleece.

New system, improved lighting… now, if there were only more than 24 hours in a day…